Precision Metal Cutting Services for Every Application

At Accutek, we provide advanced metal cutting services engineered for accuracy, speed, and efficiency across all project scales. Whether you need to intricate precision cuts, thick-plate processing, or tube and structural cutting, our state-of-the-art equipment delivers consistent, high-quality results.

From stainless steel, mild steel, and aluminum to custom profiles and tubing, we ensure clean, reliable cuts that meet your exact specifications.

Accutek Industries – Cutting Capabilities

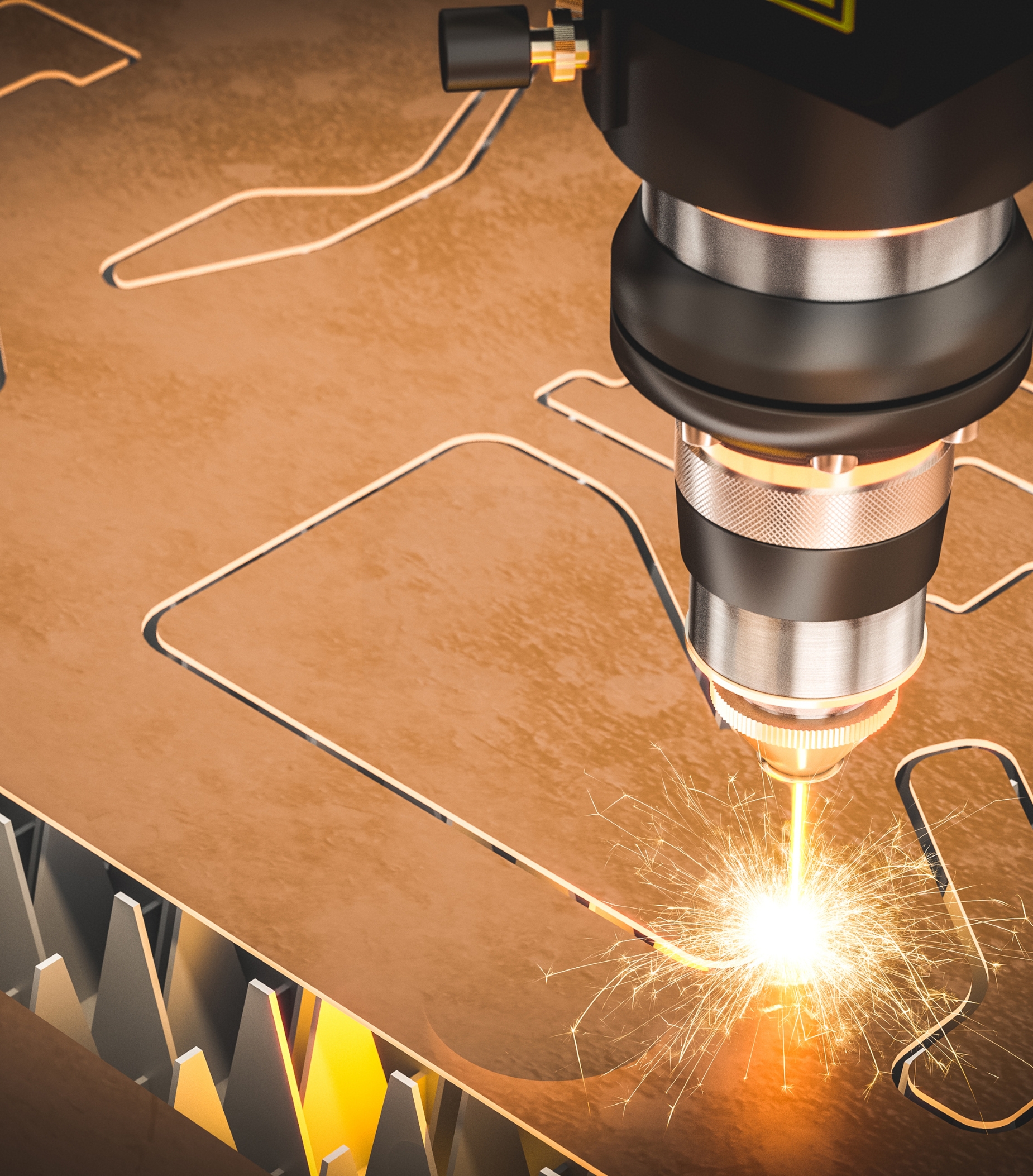

CNC Laser Cutting

Our laser cutting department delivers high-speed, high-precision cutting for complex shapes, tight tolerances, and production-grade accuracy.

Equipped with twin 6′ × 13′ shuttle tables and a modern Accutek 3000W laser system, we deliver exceptional cut quality with minimal heat-affected zones.

Cutting Capacities:

- • Mild Steel: up to 3/4″

- • Stainless Steel: up to 5/8″

- • Aluminum: up to 1/2″

- • Ability to cut extremely thin material down to .003″

- • Repeatability: 99.8%

- • Accuracy: ±0.002″

Advantages:

✔ Smooth, burr-free edges

✔ Ideal for intricate parts & high production

✔ Excellent edge quality & minimal HAZ

Laser Tube Cutting

Our tube laser capabilities allow precise cutting of:

• Round tubing

• Square tubing

• Rectangular tubing

• Pipe-based structures

Advantages:

✔ Complex notches, coping, and cutouts

✔ High repeatability

✔ Reduces or eliminates secondary machining

✔ Ideal for frames, enclosures, machine structures

Waterjet Cutting

Using Flow International’s 60,000 PSI MACH 2C Dynamic Head Waterjet with Active Tolerance Control, we provide precision cutting for materials that cannot tolerate heat or edge distortion.

Technical Specifications:

- • Kerf width: ~0.01″

- • Tolerance: ±0.005″

- • Taper: <1°

- • Cuts virtually any material

- • No heat-affected zone and no distortion

Advantages:

✔ Superior accuracy for complex shapes

✔ Ideal for heat-sensitive materials

✔ Clean, precise edges with no thermal stresses

CNC Plasma & Flame Cutting

Our heavy-plate cutting department utilizes two large-format Koike Aronson Plate Pro 2006 systems, each with a 96′ × 24′ cutting area. These machines allow us to process everything from thin sheet metal to extremely thick steel plates with accuracy and consistency.

Plasma Cutting

- • Suitable for stainless steel, aluminum, and mild steel

- • Cutting range: 16 gauge to 1″

- • Accuracy: ±1/16″

- • Fast, productive, and cost-effective for medium-thickness materials

Flame Cutting

- • Designed for heavy-duty steel plate

- • Cutting range: 1/4″ to 6″ mild steel

- •Accuracy: ±1/16″

- • Ideal for structural and industrial applications requiring thick material

Combined Benefits:

✔ Versatility for thin to very thick plate

✔ Economical options based on material & thickness

✔ Large-format cutting for oversized projects

✔ Reliable accuracy with industrial-grade performance

Saw Cutting & Drilling

We provide precision sawing and drilling for structural profiles, tubing, bars, and flat materials—ensuring consistent, clean cuts for fabrication and structural applications.

Advantages:

✔ Accurate lengths, angles, and hole placement

✔ Minimal distortion

✔ Suitable for framing, supports, and fabrication work

Industries We Serve

- • Construction & Infrastructure

• Automotive & Transportation

• Industrial Fabrication & Manufacturing

• Equipment & Machinery Manufacturing

• Architectural & Custom Metalwork

Why Choose Accutek Industries

- • Multi-method cutting capabilities (Laser, Tube Laser, Waterjet, Plasma, Flame, Sawing)

• High precision and high production capacity

• Fast lead times & competitive pricing

• Prototype, small batch & mass production support

• Reliable quality control and experienced operators