Modern manufacturing demands speed, accuracy, and dependable quality—no exceptions. Whether you’re producing components for construction, industrial machinery, automotive applications, or custom fabrication, deadlines are tighter, and expectations are higher than ever. That’s exactly where Laser Tube Cutting Services delivers a powerful advantage.

As manufacturers search for ways to cut production costs, reduce waste, and accelerate turnaround times, laser tube cutting has emerged as one of the most valuable and efficient solutions available today. Its unmatched precision, versatility, and speed make it a preferred choice for businesses that rely on high-quality metal components delivered on schedule.

In this blog, we break down how laser tube cutting dramatically reduces manufacturing time and boosts overall efficiency—and why partnering with the right experts matters.

-

What Makes Laser Tube Cutting Services a Game Changer?

Today’s industries require components that fit perfectly, perform reliably, and meet strict engineering requirements. Traditional cutting methods often struggle to maintain consistent quality across large production volumes. Manual cutting and older mechanical systems can introduce errors, slow down production, and increase material waste.

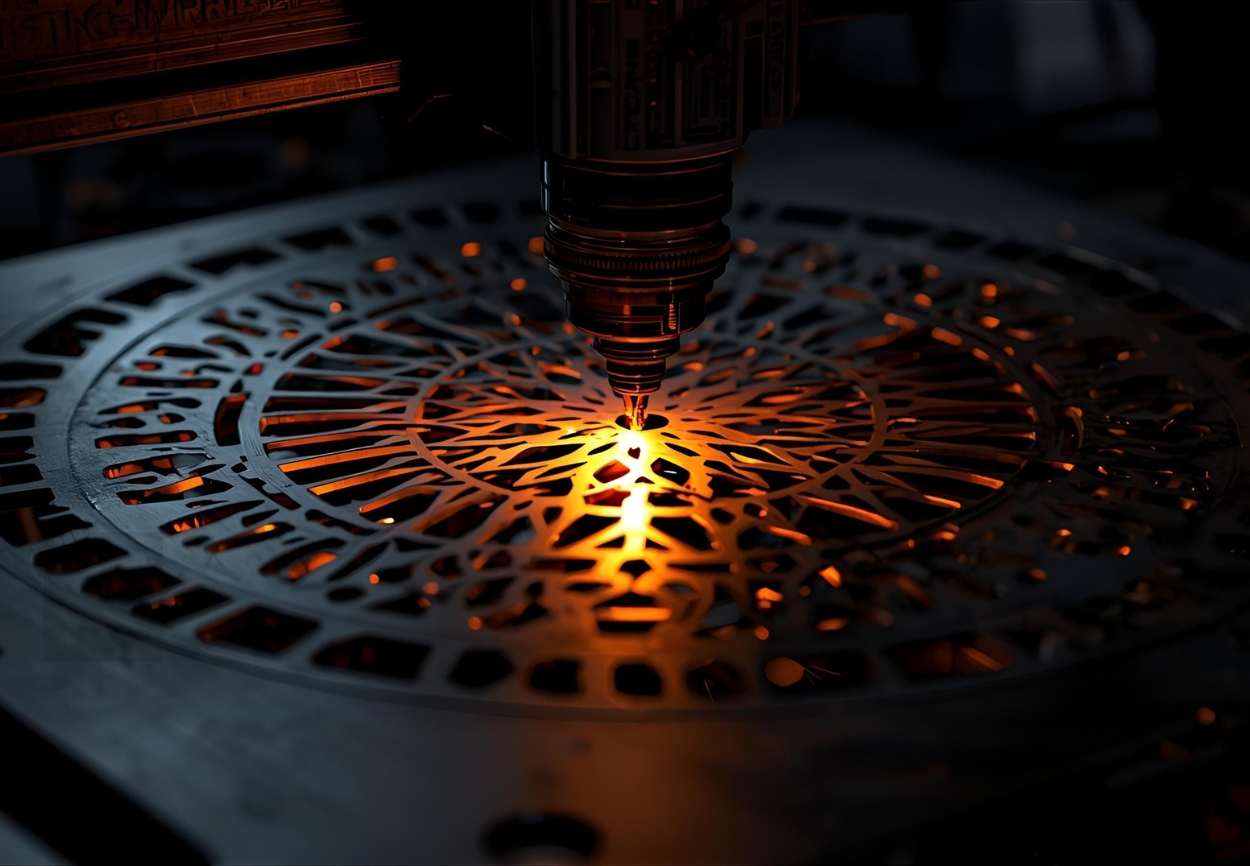

Laser Tube Cutting Services solve these problems by using high-powered laser beams that cut through metal with extreme accuracy. This technology ensures:

- Consistent, repeatable quality

- Smooth and clean edges without post-processing

- Fast cutting speeds compared to conventional tools

- Minimal distortion even on complex shapes

For manufacturers under pressure to meet deadlines and maintain product quality, these advantages are transformational.

-

Faster Processing Speeds Lead to Shorter Production Cycles

One of the biggest reasons companies invest in Laser Tube Cutting Services is speed. Laser systems cut significantly faster than saws, torches, or manual processes—while maintaining far greater precision.

Here’s how they accelerate production:

- High-speed beam movement enables rapid cutting of multiple shapes and sizes

- Automated feeding systems reduce the need for manual handling

- No tool changes are required for different patterns or materials

- Reduced downtime since lasers require minimal maintenance during operation

For industries working with high-volume orders or time-sensitive contracts, these time savings directly translate to improved delivery performance.

-

Precision That Eliminates Rework and Material Waste

Rework is one of the biggest hidden costs in manufacturing. Every incorrectly cut tube, misaligned hole, or uneven edge adds extra labour, wasted material, and production delays.

Laser Tube Cutting Services drastically reduce these issues because the laser beam produces:

- Highly accurate cuts within tight tolerances

- Perfectly smooth edges with minimal heat impact

- Precise replication of complex shapes

- Accurate positioning of slots, holes, and contours

This level of precision means fewer errors and far less rework—saving manufacturers with significant time and money. The improved accuracy also allows for tighter-fitting assemblies and better structural performance in final products.

-

Automation Enhances Efficiency and Reduces ManualLabour

Modern manufacturing requires a high level of automation to stay competitive. Laser systems integrate easily with automated software and machinery, allowing companies to streamline production from end to end.

With Laser Tube Cutting Services, you get:

- CAD-to-machine automation for quick programming

- Batch production capabilities with minimal manual input

- Reduced need for skilled labour in manual cutting tasks

- Consistent results even across thousands of parts

Automation ensures predictable manufacturing timelines and allows teams to focus on more skilled tasks like quality assurance, assembly, or logistics.

-

Versatility for Wide Ranges of Materials and Designs

Manufacturers often work with tubes, pipes, and structural components that vary in thickness, diameter, and material type. Traditional cutting tools may struggle or require frequent adjustments.

But with Laser Tube Cutting Services, versatility becomes an advantage:

- Works efficiently on steel, stainless steel, aluminum, and alloys

- Handles round, square, rectangular, and custom-shaped tubes

- Cuts intricate patterns, angles, and specialty designs

- Adapts easily to both small and large production runs

This flexibility means fewer equipment changes and smoother workflows—another key contributor to increased efficiency.

-

Improved Assembly Speed Through More Accurate Fitment

A precise cut doesn’t just help during manufacturing—it also improves all downstream processes. Components that fit perfectly reduce assembly time and minimize the need for adjustments.

Laser-cut tubes streamline assembly by providing:

- Accurate alignment points

- Perfectly cut openings for welds, bolts, or fittings

- Clean surfaces that require little to no prep work

- Consistent sizing that speeds up batching and installation

Companies that rely on welders, fitters, and assemblers immediately notice the difference: faster builds, fewer errors, and smoother workflow transitions.

-

Long-Term Savings Through Higher Productivity and Lower Waste

While laser systems are advanced, their long-term benefits far outweigh traditional cutting tools. Manufacturers using Laser Tube Cutting Services often see measurable long-term savings due to:

- Reduced consumable expenses (no blades or cutting fluids)

- Lower labour costs

- Higher machine uptime

- Less wasted raw material

- Faster completion of contracts

The result? A more productive, cost-effective manufacturing operation.

-

Why ChooseAccutekIndustries for Laser Tube Cutting?

If you’re looking for precision, speed, and reliability, Accutek Industries delivers industry-leading Laser Tube Cutting Services backed by advanced technology and expert technicians. We understand the pressures of modern manufacturing and provide solutions built around:

- High-capacity production capabilities

- Accurate cutting for even the most complex designs

- Fast turnaround times

- Consistent, repeatable quality

- Detailed attention to client requirements

Our commitment to precision and efficiency ensures your manufacturing process becomes quicker, smoother, and far more cost-effective.

Ready to Improve Manufacturing Speed and Efficiency? Let’s Get Started.

Accelerate your production and achieve flawless results with Accutek Industries’ advanced laser cutting technology.

Contact us today for a customized quote and discover how our Laser Tube Cutting Services can transform your manufacturing workflow.

Contact us: 604-626-4700

Location: 4848 275 St Unit-204, Langley Twp, BC V4W 0A3

Follow Us:

Facebook: https://www.facebook.com/people/Accutek-Industires-Ltd/61579864413995/

Instagram: https://www.instagram.com/accuteklangley/

Post A Comment