When precision and efficiency meet, laser cutting services emerge as one of the most advanced fabrication methods available today. Whether you’re in manufacturing, construction, or custom metal design, laser cutting plays a vital role in producing accurate and clean results. But one question often arises among clients and designers alike – how many thicknesses of metal can laser cutting machines actually handle?

In this blog by Accutek Industries, we’ll explore the capabilities of modern laser cutting machines, factors that affect cutting thickness, and why professional laser cutting services are essential for consistent, high-quality results.

1. Understanding Laser Cutting Services and Their Importance

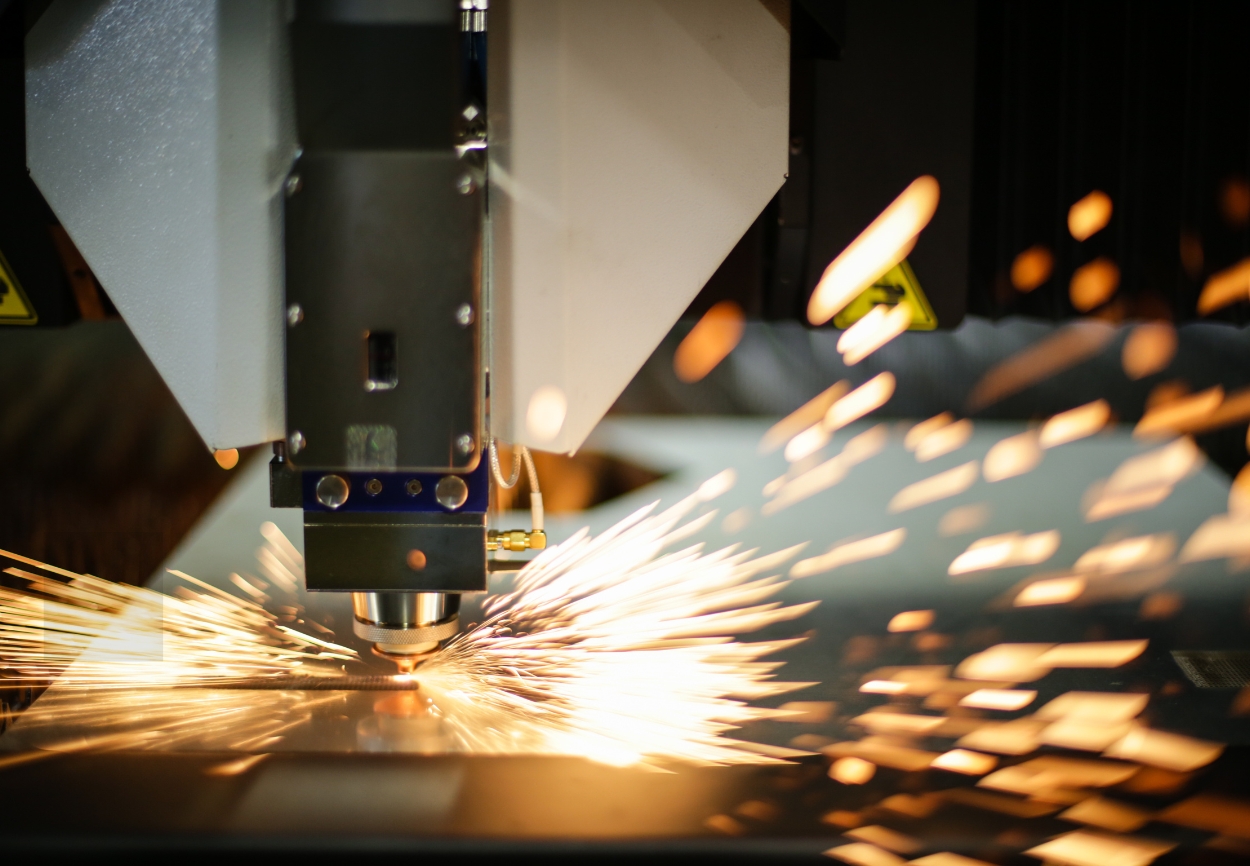

Laser cutting services use a focused beam of light to cut, engrave, or shape metal materials with extreme accuracy. This technology is widely used in industrial manufacturing, architecture, automotive, and even art and signage applications.

The beauty of laser cutting lies in its ability to make intricate cuts with minimal waste and maximum precision. It works by melting or vaporizing material along a defined path, allowing for clean edges and smooth finishes.

At Accutek Industries, our laser cutting services are designed to deliver top-tier accuracy for various metal types – including steel, aluminum, copper, and stainless steel – across different thicknesses.

2. Factors That Affect the Thickness a Laser Can Cut

The thickness that laser cutting services can handle depends on several factors:

Laser Power: Measured in watts, the power of the laser determines how deep it can be cut. Higher wattage lasers (e.g., 6kW–12kW) can slice through thicker materials compared to lower-powered ones.

Metal Type: Reflective materials like aluminum and copper are harder to cut due to their heat reflection properties.

Assist Gas Used: Oxygen, nitrogen, or air are used to blow away molten material and influence cut quality and speed.

Machine Technology: Fiber lasers, for example, are more efficient with thin to medium materials, while CO₂ lasers perform better with thicker sections.

By balancing these variables, professional laser cutting services can achieve precise results even with challenging materials.

3. Common Metal Thickness Ranges Handled by Laser Cutting Services

Modern laser cutting machines are versatile enough to handle a broad range of metal thicknesses. Here’s an overview of what you can typically expect:

Mild Steel

Up to 25–30mm thick with high-powered fiber lasers

Produces clean, burr-free cuts

Excellent for structural and industrial applications

Stainless Steel

Handles up to 25mm depending on laser power and gas used

Nitrogen-assisted cutting gives oxide-free edges

Aluminum

Up to 20–25mm with advanced fiber lasers

Requires precise settings due to reflectivity

Brass and Copper

Usually up to 12–15mm, since these materials reflect laser beams

Fiber lasers are ideal for cutting these non-ferrous metals

At Accutek Industries, our laser cutting services utilize high-powered, computer-controlled laser machines capable of cutting metals across multiple thicknesses – while maintaining pinpoint precision.

4. Why Laser Cutting Is the Ideal Choice for Different Thicknesses

Whether your project involves thin sheets or heavy-gauge plates, laser cutting services offer unmatched versatility. Here’s why:

For Thin Metals (1–6mm): Laser cutting is exceptionally fast, with clean, sharp lines – perfect for signage, decorative panels, and light components.

For Medium Thickness (6–15mm): It provides a balance of precision and speed, ideal for mechanical parts or structural components.

For Thick Metals (15mm+): High-powered lasers and assist gases ensure deep cuts without distortion, suitable for heavy-duty industrial applications.

This adaptability makes laser cutting one of the most dependable fabrication solutions in today’s metalworking industry.

5. The Role of Expertise in Laser Cutting Services

Even the best machines can’t guarantee top results without skilled technicians behind them. When choosing laser cutting services, the provider’s experience plays a crucial role in handling different material thicknesses.

Professionals at Accutek Industries understand how to adjust cutting speeds, power intensity, and assist gas combinations for every type of metal. This ensures:

Consistent cut quality across various thicknesses

Minimal thermal damage or warping

Efficient use of material, reducing waste

Our expert team ensures that each project – from thin aluminum sheets to thick steel plates – is executed with the highest accuracy and efficiency.

6. Benefits of Partnering with Professional Laser Cutting Services

When you choose Accutek Industries for laser cutting services, you gain access to:

High Precision: Advanced laser systems guarantee exact dimensions and smooth finishes.

Speed & Efficiency: Faster turnaround times compared to mechanical cutting.

Design Flexibility: Ability to produce intricate patterns and detailed components.

Cost-Effectiveness: Reduced waste and post-processing mean better value.

Versatility: Suitable for diverse materials and thickness levels.

Whether you’re producing prototypes, small batches, or large-scale industrial parts, our state-of-the-art facilities can handle your needs efficiently.

7. How to Choose the Right Laser Cutting Partner

Not all laser cutting services are created equal. When selecting a company, consider the following:

Technology Used: Ensure they have modern fiber or CO₂ lasers.

Experience Level: Look for proven results across various industries.

Material Capabilities: Confirm they can cut your specific metal type and thickness.

Quality Control: Ask about inspection and tolerance standards.

Turnaround Time: Choose a partner who respects deadlines.

At Accutek Industries, we take pride in offering reliable laser cutting services that exceed client expectations in quality, precision, and delivery speed.

8. Typical Applications for Different Thicknesses

Depending on your project requirements, laser cutting can support a range of applications:

Thin Metal Sheets: Automotive panels, decorative screens, electrical enclosures

Medium Thickness Metals: Structural frames, machine parts, industrial brackets

Thick Metal Plates: Heavy machinery components, construction supports, custom equipment

Each category requires different cutting techniques – all of which Accutek Industries handles precision and care.

Conclusion: Choose Accutek Industries for Precision Laser Cutting Services

In summary, modern laser cutting machines can handle a wide range of metal thicknesses – from ultra-thin sheets to thick industrial plates — depending on the machine’s power and technology. However, achieving accurate, high-quality cuts requires more than just equipment; it demands experience, precision, and attention to detail.

At Accutek Industries, we combine cutting-edge technology with years of expertise to deliver dependable laser cutting services for every project. Whether you need custom prototypes, detailed components, or large-scale production, our team ensures precision, efficiency, and excellence from start to finish.

Looking for professional laser cutting services that deliver unmatched precision and speed?

Contact Accutek Industries today for a free consultation and quote. Our team is ready to help you bring your design to life – with accuracy, reliability, and the highest quality standards.

Contact us: 604-626-4700

Location: 4848 275 St Unit-204, Langley Twp, BC V4W 0A3

Follow Us:

Facebook: https://www.facebook.com/people/Accutek-Industires-Ltd/61579864413995/

Instagram: https://www.instagram.com/accuteklangley/

Post A Comment