When it comes to achieving precision, speed, and efficiency in metal fabrication, laser cutting for stainless steel has become a top choice among manufacturers and fabricators. Whether you’re producing intricate components, custom parts, or large industrial pieces, this cutting-edge method delivers superior results compared to traditional cutting techniques.

In this blog, we’ll explore why laser cutting for stainless steel stands out, its many advantages over conventional methods, and how it can significantly enhance both the quality and efficiency of your production process.

1. Precision and Accuracy: The Hallmarks of Laser Cutting for Stainless Steel

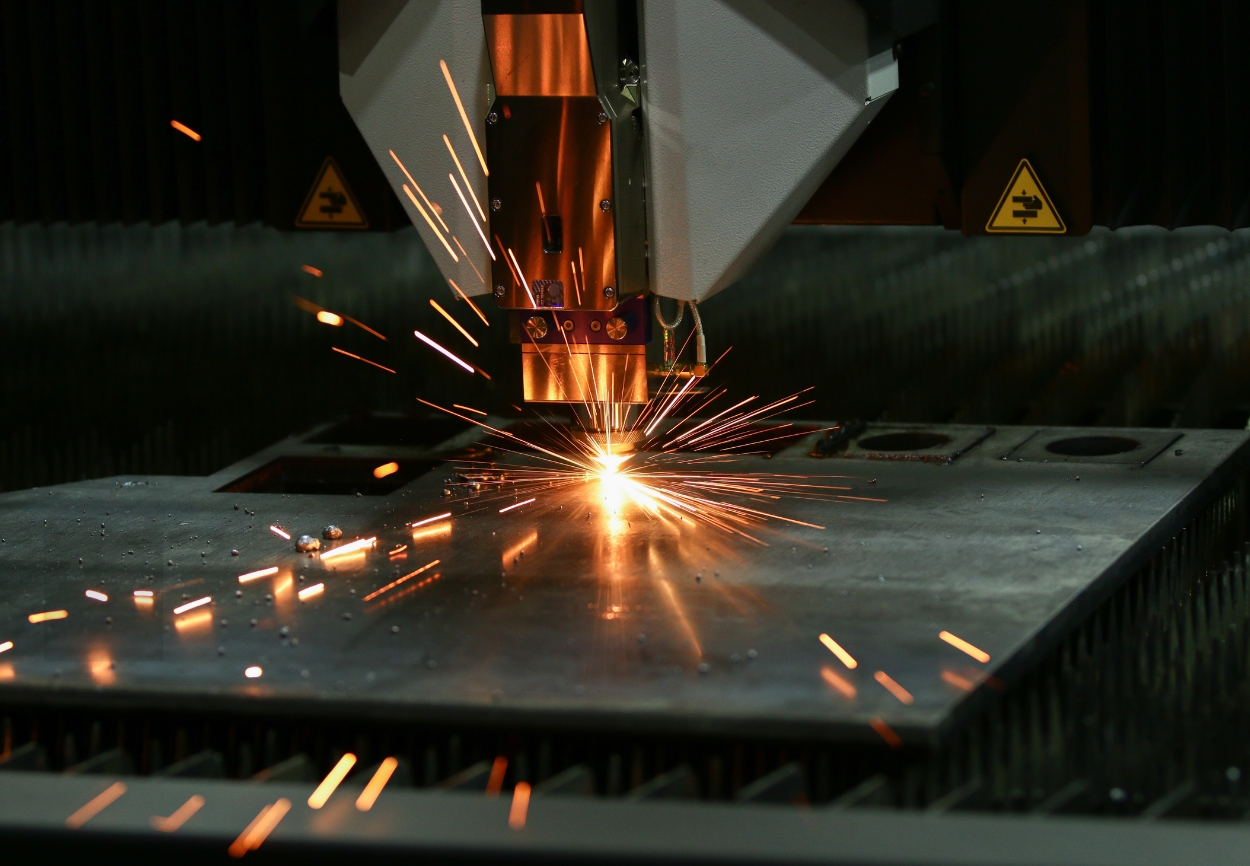

One of the biggest advantages of laser cutting for stainless steel is its unmatched precision. Laser technology uses a focused beam of light to make highly accurate cuts, ensuring clean edges and detailed designs without the need for secondary finishing.

Unlike mechanical cutting methods that rely on physical contact and can cause material distortion, laser cutting minimizes the risk of deformation. This precision makes it ideal for industries like aerospace, automotive, construction, and electronics—where even a fraction of a millimeter can make a difference.

Key Benefit: You get smooth, burr-free edges that reduce the need for additional polishing or grinding—saving both time and cost.

2. Speed and Efficiency: Faster Turnaround with Laser Technology

When compared to plasma or waterjet cutting, laser cutting for stainless steel is much faster, especially for thinner materials. The laser beam’s ability to cut continuously and at high speeds means shorter production times and faster project completion.

This efficiency makes it perfect for businesses handling bulk or repeat orders. Whether you’re cutting small components or large panels, laser cutting ensures consistent performance across all units, without compromising accuracy.

Pro Tip: If your goal is to meet tight deadlines without sacrificing quality, laser cutting is your go-to method.

3. Minimal Waste and Maximum Material Utilization

Sustainability and cost-effectiveness are major considerations in modern fabrication. Laser cutting for stainless steel produces minimal waste due to its narrow kerf (cutting width), allowing for more precise material use.

Computer-controlled laser cutters can also nest multiple parts closely together on a single sheet, maximizing yield and minimizing scrap. This makes laser cutting an environmentally friendly choice and helps reduce material costs—especially important when working with expensive metals like stainless steel.

Key Takeaway: You’ll save on raw materials while maintaining a greener, more efficient production process.

4. Versatility Across Thicknesses and Applications

Laser cutting for stainless steel is highly versatile—it can handle a variety of thicknesses, from ultra-thin sheets used in electronics to thick industrial plates used in machinery or structural projects.

Beyond cutting, lasers can also perform engraving, marking, etching, adding logos, serial numbers, or intricate decorative patterns to your products. This flexibility allows fabricators to meet a wide range of customer requirements, all with a single piece of equipment.

Applications include:

- Custom enclosures and panels

- Machine components

- Kitchen and architectural fixtures

- Signage and display elements

Whether you need one-off prototypes or large-scale production, laser cutting offers the adaptability your project demands.

5. Reduced Maintenance and Longer Tool Life

Traditional cutting methods often involve direct contact between tools and materials, leading to wear and tear over time. With laser cutting for stainless steel, there’s no contact between the cutting tool and the material, meaning minimal mechanical stress and virtually no tool degradation.

This translates to lower maintenance costs, fewer equipment downtimes, and consistent performance throughout the project’s lifespan. In industries where uptime is critical, this reliability can have a major impact on overall productivity.

Benefit: More consistent output and reduced maintenance mean better operational efficiency and cost savings over the long term.

6. Cleaner Cuts and a Polished Finish

One of the reasons why many fabricators prefer laser cutting for stainless steel is the clean, polished finish it provides right out of the machine. The laser beam melts rather than tears through the metal, resulting in a smoother surface and minimal oxidation.

This is particularly beneficial for stainless steel, which is often used in visible or high-end applications—such as kitchen appliances, interior fixtures, or architectural details—where appearance matters just as much as performance.

Result: Fewer post-processing steps and a premium-quality finish that enhances your product’s visual appeal.

7. Integration with Digital Fabrication and Automation

Modern laser cutting for stainless steel systems are fully compatible with CAD/CAM software, enabling seamless integration into automated production lines. This digital precision allows for faster setup, easier design changes, and consistent quality across multiple batches.

Automation also reduces human error, ensuring that every cut matches the intended design exactly. For businesses seeking scalability and consistency, this makes laser cut a future-ready investment.

Pro Tip: Partnering with a metal fabrication company that offers advanced laser cutting capabilities ensures you benefit from both precision and efficiency.

Conclusion: Choose Accutek Industries for Precision Laser Cutting in Vancouver

When it comes to laser cutting for stainless steel, Accutek Industries stands as one of Vancouver’s trusted experts. Our advanced technology, skilled technicians, and commitment to quality make us the ideal partner for all your stainless-steel fabrication needs.

Whether you require precision parts, custom panels, or large-scale production, we ensure every cut meets the highest standards of accuracy and finish.

Looking for high-quality laser cutting for stainless steel in Vancouver?

Contact Accutek Industries today for expert consultation, competitive pricing, and on-time delivery.

Let’s bring your metal fabrication projects to life with precision, speed, and reliability.

Contact us: 604-626-4700

Location: 4848 275 St Unit-204, Langley Twp, BC V4W 0A3

Follow Us:

Facebook: https://www.facebook.com/people/Accutek-Industires-Ltd/61579864413995/

Instagram: https://www.instagram.com/accuteklangley/

Post A Comment